201 — Advanced Filtration for Flyte Personal Protection System

Our team was tasked with the design of an attachable device for the helmet and hood of Stryker’s Flyte Personal Protection System with N95-equivalent filtration, per Occupational Safety and Health Administration (OSHA) and Centers for Disease Control and Prevention (CDC) recommendations. This project addresses the lack of N95-equivalent protection from airborne viruses like SARS-CoV-2.

202 — Dry Combat Submersible Regenerative Charging System

The purpose of this project is to assist in the development of the SEAL Delivery Vehicle Team TWO (SDVT-2) Dry Combat Submersible (DCS), specifically the energy potential of the onboard battery system, through developing an energy regeneration system to capture energy from underwater tides. The project focuses on two cases: using the main propeller and motor as a source of regeneration; and attaching an additional device to the hull to regenerate energy.

203 — ECE Underwater Acoustic Modem

The goal of the underwater acoustic modem project is to develop an inexpensive underwater

acoustic modem, including a field programmable gate array (FPGA) based modem, underwater

transducer, and power amplifier. The main purpose of this modem is to allow researchers

to communicate between underwater nodes and autonomous underwater vehicles (AUVs)

in a robust fashion. This project is currently in its second phase. In this phase

the team is developing the modem receiver FPGA modules, a custom prototype power

amplifier circuit board, and modeling a custom underwater transducer.

204 — ITC Cell Signal Measurement Tool

ITC has substations in areas with poor cell signal coverage. Access to communications

equipment is needed at these locations, and cell signal

boosters can be used to increase the signal. The problem: What direction should the

cell signal booster antenna be pointed? The team created a device to measure cell

signal across multiple bands. It can be connected to an existing or portable antenna

to determine the best direction to point the antenna based on possible service providers.

The device was created to provide a methodical way to determine the best direction

for the antenna in a way that can be reproduced by ITC employees across the country

for under $1,000.

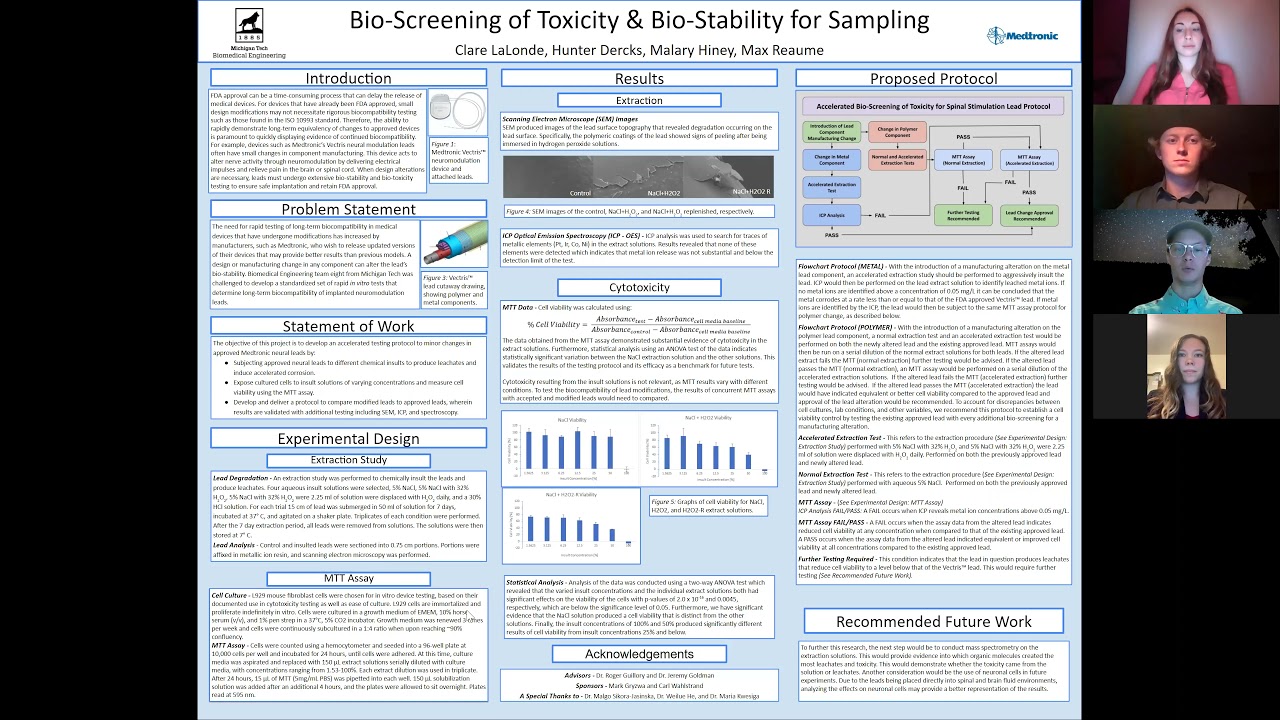

205 — Bio-Screening of Toxicity and Bio-Stability for Sampling

The need for rapid testing of long-term biocompatibility in medical devices that have undergone modifications has increased, spurred by manufacturers who wish to release updated versions of their devices that may provide better results than previous models. The goal of this project is to identify, conduct, and evaluate a set of rapid, standardized in vitro tests that determine long-term biocompatibility of implanted neuromodulation leads. The project was completed by conducting an extraction study on the leads in various solutions, cell culturing, and an MTT assay where data were collected, as well as a theorized flowchart of the next steps in testing to be completed based on previous bioevaluation reports provided by Medtronic.

206 — Confidential Project

Due to proprietary information of a commercial nature, the team has withdrawn from judging.

207 — 3D Modeling of Complex Vascular Anatomies in Anterior Spine Access Surgery

Anterior lumbar interbody fusion (ALIF) surgery allows surgeons the best access at intervertebral discs compared to posterior access. However, when working from the anterior side, a surgeon must first navigate through muscle, intestines, and, most critically, vascular structures. The goal of this project is to create a streamlined process for ALIF surgeons to take medical images and create 3D models of the vascular and bony structures so they may prepare for surgery more thoroughly.

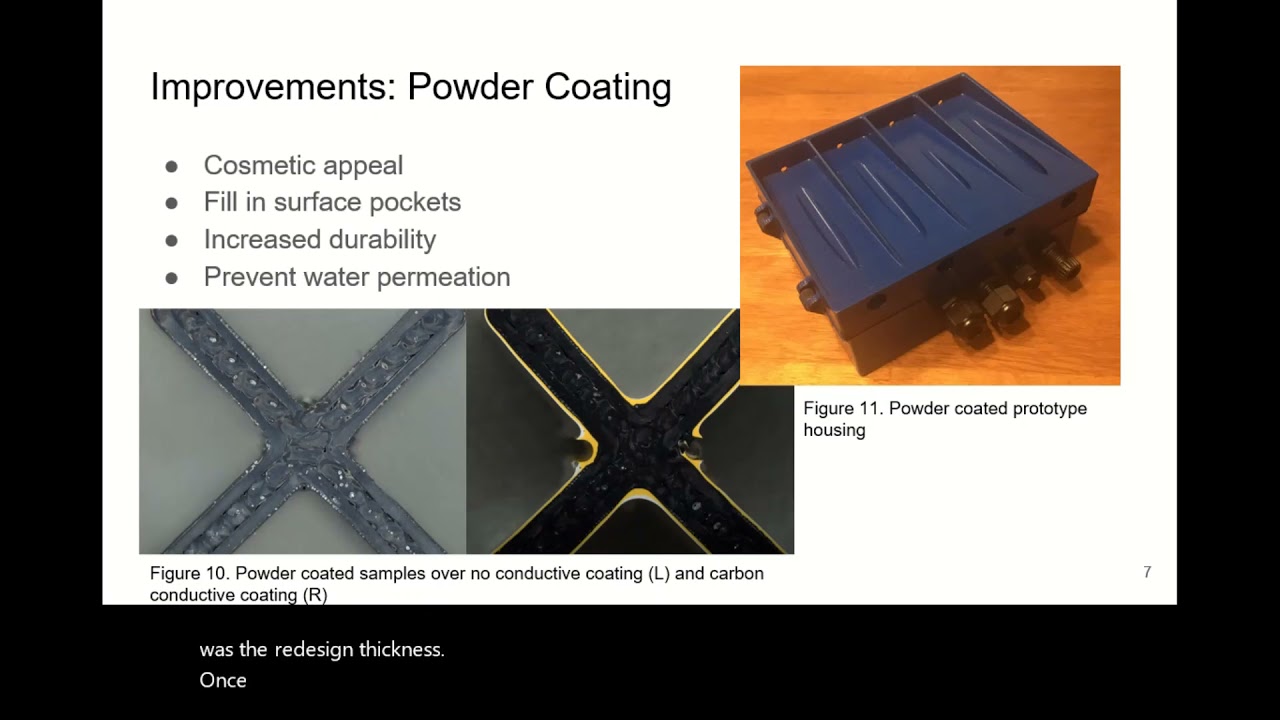

208 — Phoenix Haus Panelized Passive Home Mechanical Connection Improvements

Phoenix Haus manufactures panelized passive homes. A passive house is very energy efficient and meets the requirements set by the Passive Home Institute US (PHIUS). These houses are constructed in panels in a manufacturing facility, which allows increased build efficiency and quality. The team’s role in this project is to research and suggest design process improvements that allow Phoenix aus to do more in their manufacturing facility before panels are shipped to the job site. These design improvements will allow Phoenix Haus to increase construction efficiency of their panelized passive homes.

209 — EMP Mitigation Testing Phase 2

We developed a procedure for testing the shielding effectiveness of an enclosure produced by Systems Control following the IEEE standard 299. As a supplement to the procedure, the team also provided an equipment specification list, background characterization procedure, and enclosure characterization procedure. The test procedure, including characterization and a completed test report, was conducted on one of the enclosures at Systems Control in Iron Mountain, Michigan.

210 — Trailer Articulation Sensing System

Our project was to create a system that tracks the angle between a trailer and the respective towing vehicle. The goal is for Horizon Global to be able to implement our system to feed a trailer backup assist feature and track trailer sway while driving. The system we have created is attached underneath the trailer tongue and hitch, and employs a capacitive encoder turned by a slip yoke to track the trailer angle. Arduino is currently being used to gather the angular data.

211 — Sampling System for Hypothesized Surface

Our team designed and prototyped a hypothetical sampling system to be used in a hypothetical Psyche mission. This system will gather physical samples from the Psyche asteroid and be integrated into a proposed mobile platform or robotic explorer, designed by a separate SCD team.

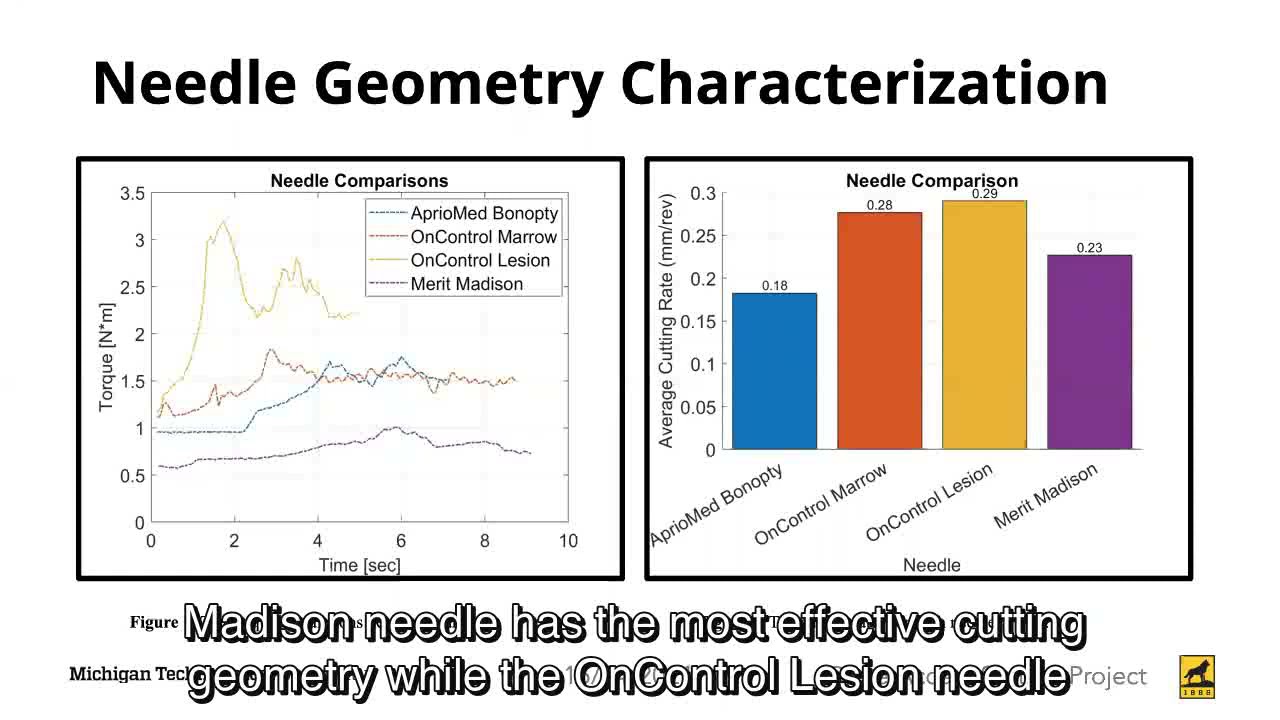

Bone access systems are used for diagnostic purposes, surgical procedures, and medical device implantation. One of the most important variables to determine the success of the access procedure is the cutting effectiveness of the needle. Currently, interventional bone access procedures are typically performed with a manual technique, but are moving towards a powered method to reduce procedure time and patient pain. This project will determine a bone analog to test the current powered system and needle designs as well as characterize powered and manual needles currently on the market.

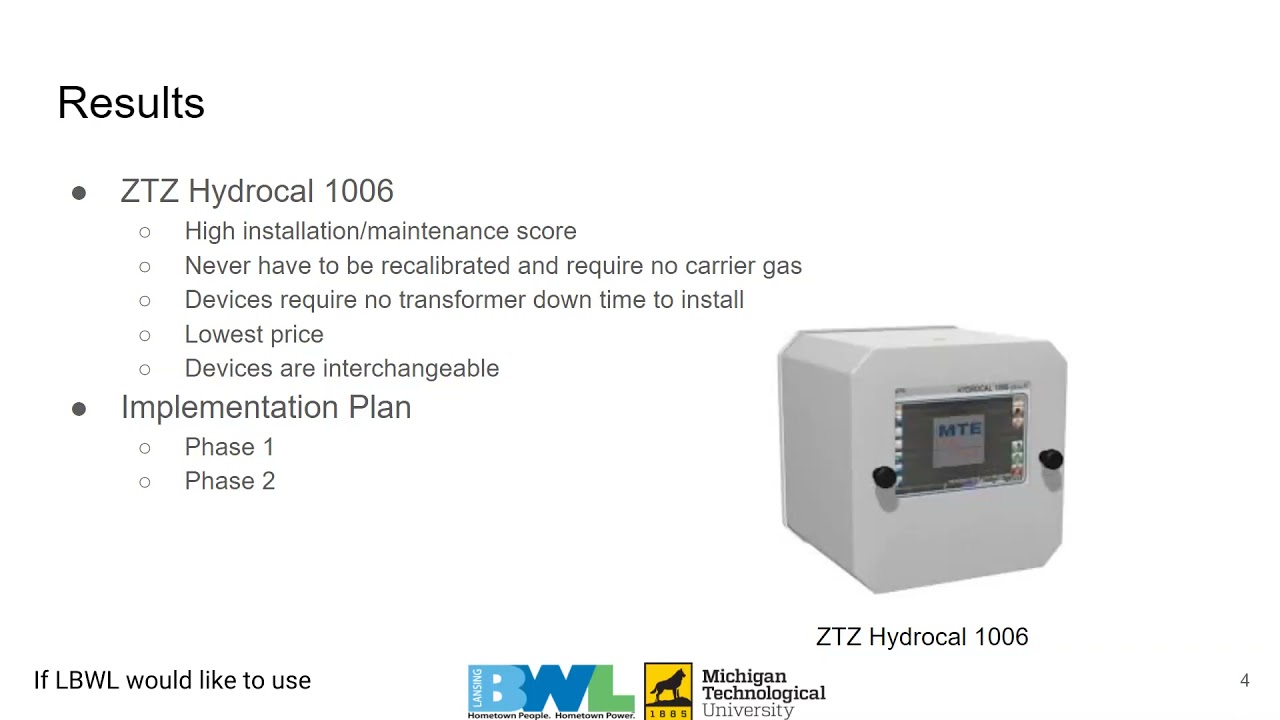

213 — Substation Transformer Monitoring System

The mission of this project is to get a great background and understanding of dissolved gas analysis (DGA) and what it means inside a transformer, then use that knowledge to determine a DGA monitoring system that best fits the needs of Lansing Board of Water and Light. There is a wide variety of monitors available. This project includes making a plan to deploy the monitoring systems across the Lansing Board of Water and Light power system. Additional research of standard concentrations, how different oils affect DGA, and remediation when the DGA results indicate a problem is also done.

214 — Development of an Artificial Intelligence-based Image Segmentation Method for Heart Procedures

Automatic image segmentation of cardiac scans is currently slow and inaccurate, creating a need for trained personnel to perform manual corrections. Digital Imaging and Communications in Medicine (DICOM) files obtained from CT scans will be used to create an accurate model of the patient’s heart. Opensource AI packages will be used to perform the same task with greater efficiency and accuracy. A segmentation software called 3DSlicer will be used with TensorFlow AI packages to create a process where a clinician can input CT scans and receive a 3D model in an STL file. Initial models will be compared against those created manually. This process will be validated until AI detection of cardiac abnormalities has reached the desired accuracy.

215 — Hedgemony Online

Our goal was to create a web-hosted digital version of the board game Hedgemony created by the RAND Corporation. The purpose of this game is to teach strategic decision-making to players of the game such as students or military professionals.

The biggest problem faced by players is the inability to play in person right now with the high number of players required. This digital version of the game will allow players to connect remotely and perform all the actions necessary for their role while maintaining social distance with everyone else in the game. The result of this project will be a digital port of all the game’s components, which the players will be able to interact with at will.

216 — Product Redesign for Anatomical Diversity

Boston Scientific tasked our team with the redesign of a laparoscopic tissue retrieval catch bag to consider patient-specific parameters like anatomical dimensions and disparity in the targeted organs/entities. The team focused on two major components of the device: the handle and the bag opening. Improvements by the team include better grip, single-hand manipulation, and a trigger mechanism to manipulate the size of the catch bag opening to aid in navigating the surgical area. This design significantly improved the area and roundness of the catch bag opening, making it better suited for the removal of ovaries and cysts. This work could improve quality of care for patients while also aiding in ease of use for physicians.

217 — SICK Lidar Challenge: Autonomous Collision Detection and Avoidance

This project was an entry to SICK Inc.’s Tim 10K Lidar Challenge. Our entry is combining a lidar machine and a camera using sensor fusion to create commands to output to a robot, allowing it to dynamically observe a space and avoid collisions while moving. This project on a small scale would be creating a better and more efficient Roomba machine, while on a large scale could be implemented in autonomous vehicles.

218 — Hospital Washer AutoSampler

Our team was tasked with improving the mechanical functionality and design of a washer device as part of the project development phase II for Stryker. Washing and sterilizing hospital instruments after every use is key to preventing tool damage. Therefore, achieving a leakproof washer design that allows the realtime extraction of the chemical characteristics of the resulting fluid after every wash is the ultimate goal. This device will help in assessing the effects of wash environments on medical instruments and in optimizing washing cycles. parameters that were tested for include temperature, pH, conductivity, and oxidation-reduction potential. The output of data was not achieved by the previous team—created by Team 2 collectively.

219 — Algorithm Camouflage: Obfuscation from Machine Learning-trained Image and Audio Recognition Models

Urban terrain is littered with surveillance equipment that is increasingly capable of image and voice recognition, and unmanned ground and aerial systems are capable of carrying a payload that can detect intrusion using both visual and audio data. This project studies the potential methods Army Special Forces may use to obfuscate themselves from image- and audiotrained machine learning models in an airport or open expanse of terrain.

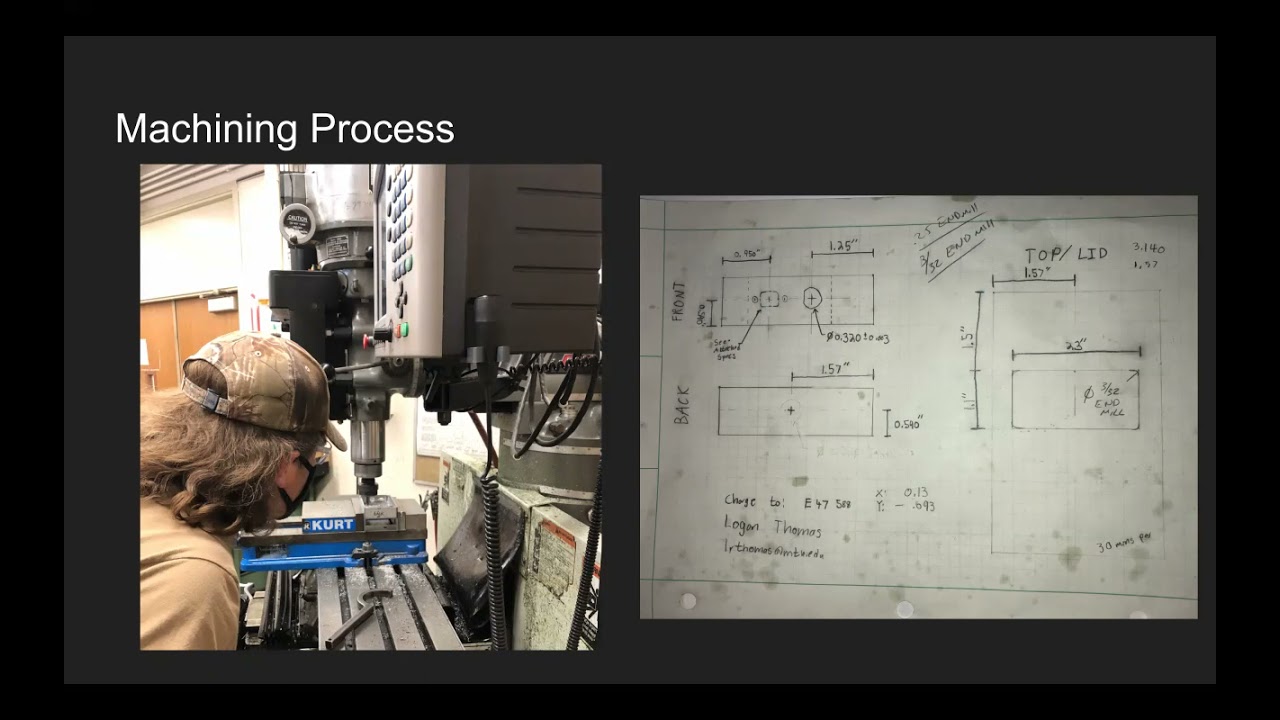

220 — Thermal Gel and Fixture

Radiofrequency (RF) ablation is a common minimally invasive procedure used to treat nerve pain. In this procedure, heat-affected regions of tissue (lesions) are produced to cauterize nerves. The development of new RF blation technologies is hindered by crude simulations relying on chicken breast. Chicken lacks uniformity, adaptability, and reusability. For this project, we have been tasked to design a fixture and testing procedure to collect thermal conductivity and impedance data in an experimental gel relative to the chicken standard. The development of an appropriate testing fixture would allow for repeatable RF ablation tests, a more accurate lesion heat map, and reduced measurement variability, which will accelerate product validation.

221 — Blubber Only Implantable Satellite Tag Anchoring System

We are designing a whale telemetry tag tip that will self-blunt its sharp edges once implanted into whale blubber and reduce longterm tissue inflammation in the whale. With the current version, the tag and tip are implanted in the whale blubber, then sharp edges of the tip cause chronic inflammation to the surrounding tissue. We have designed two tag tips with blunting mechanisms to solve this issue. One design is a biodegradable polymer tip that will blunt once implanted from degradation, which will reduce the sharpness of the edges. The second design is a retractable tip that will hide the sharp edges after an inner biodegradable cylinder degrades, allowing a spring to pull the tip back into a casing.

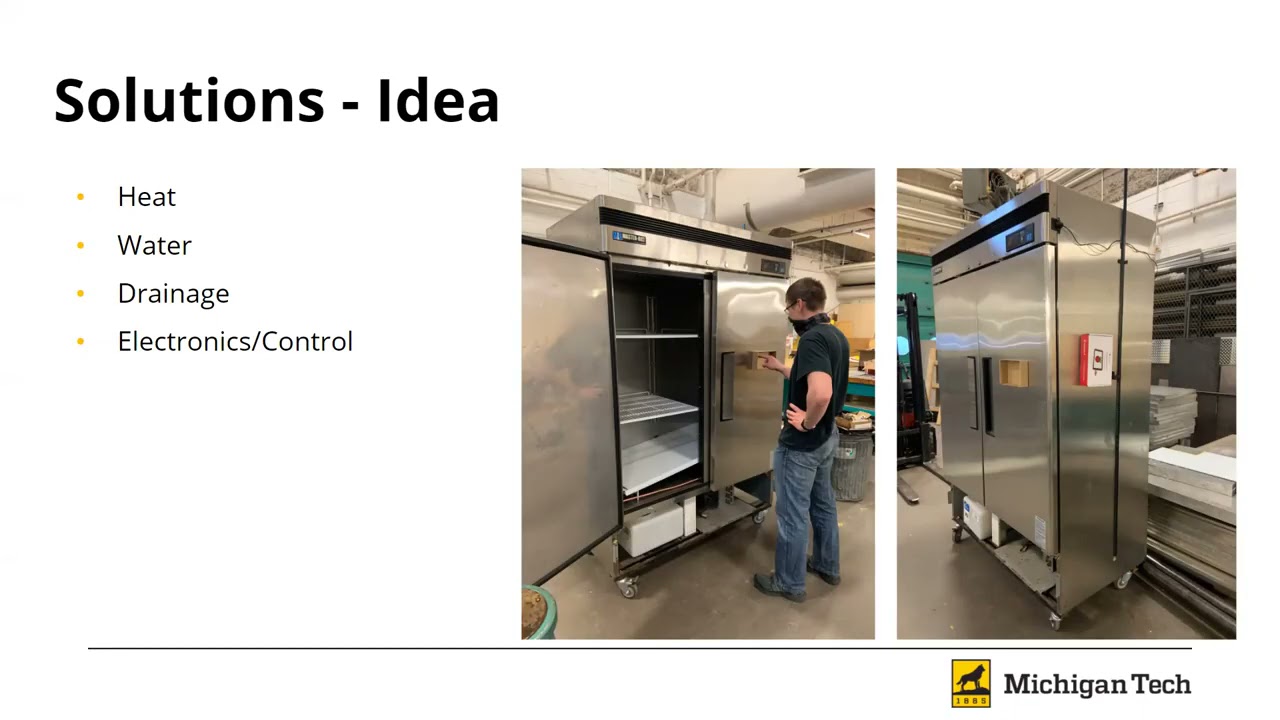

222 — MTU Scaled-down Sanitation Chamber

Using an industrial-sized Master-Bilt refrigerator, our objective for this project is to create a scaled-down mobile sanitation chamber that will allow for safe and effective decontamination of personal protective equipment during the COVID-19 pandemic and similar circumstances in the future. Our plan of action is to equip the current refrigerator with a combination of heat, water, and chemicals used to disinfect hospital rooms and equipment, all controlled using a Raspberry Pi as our operating system. The combination of these three systems allows for many possible run cycles to provide the most effective solution to the current sanitation of products.

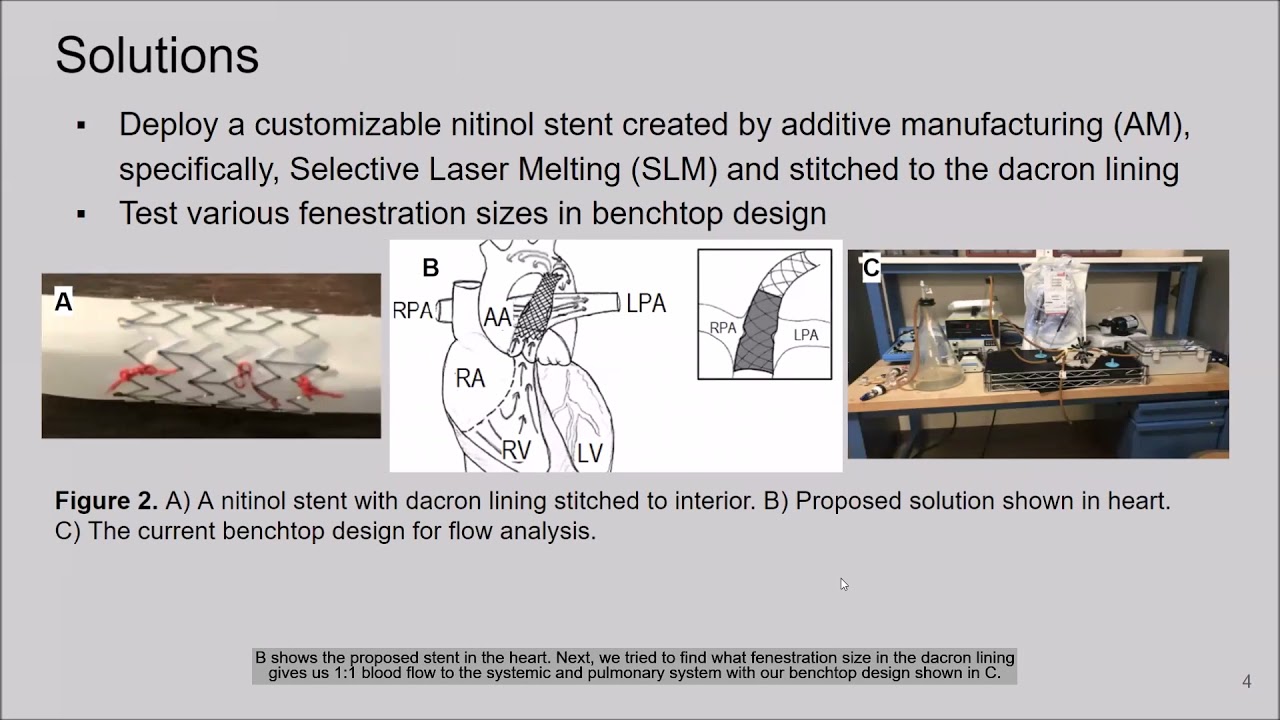

223 — Phase VI Transcatheter Single Ventricle Device Development

Hypoplastic left heart syndrome (HLHS) is a congenital defect wherein the left heart is underdeveloped and affects normal blood flow. Currently, a staged surgery is required with a stage I palliation (SIP) performed within the first week of life. The Norwood procedure or hybrid procedure is usually selected for SIP. For the hybrid procedure, a stent is percutaneously placed in the ductus arteriosus (DA) to maintain systemic circulation with banding of the pulmonary arteries via sternotomy to decrease pulmonary blood flow. Our project seeks to develop a novel approach to replace SIP with a transcatheter approach using additive manufactured, nitinol-based, and patient-specific stents to maintain systemic circulation by keeping the DA patent and decreasing pulmonary blood flow with a Dacron membrane.

224 — ITC Battery Energy Storage Scheduler

We were tasked with creating a program that will generate a daily optimized battery charging and discharging schedule for ITC’s battery system. This schedule is based off of next-day load predictions using weather as an indicator. The goal of this project is to eliminate the possibility of the solar having to be turned off due to overproduction while also optimizing the use of the battery system.

225 — Tube Roller

Our project is a tube roller for the machine shop here at Michigan Tech. The goal of the roller is to bend one-inch to three-inch OD tube for other students to use. The design of the tube roller will be driven by hand and mounted to a table. The tube roller would be able to get picked up and moved to another location if necessary, but would be required to be bolted down in the new location.

226 — Power Platform

Delfab Inc. out of Gladstone, Michigan, has requested our help in developing a powered liftgate platform for use on the back of commercial trucks. Delfab has requested that the lift enable both truck-to-ground loading/unloading and also loading/unloading at commercial loading docks. They’ve also asked for a chain and sprocket drive system as opposed to the typical hydraulic system.

Our project is an energy management system designed to provide a durable and lightweight backup battery supply for foot soldiers. This energy management system needs to be waterproof, airworthy, and able to withstand extreme conditions, such as high or low temperatures and being dropped from various heights.

228 — Locomotive Traction Motor Field Service Apparatus

Our team has been engaged by BNSF to design a subsystem of a locomotive traction motor field service apparatus (LTMFSA) to innovate the repair process for seized locomotive axles. The current process utilizes an oxyacetylene torch, which is hazardous for the operating technician. The job completion time can also vary from 20 minutes to five hours. The project that Team 20 is focusing on is the cutting method, which will be integrated with an already existing feed apparatus designed by Team 52 last semester. Using an array of thermal lances and oxygen, the time for completion as well as the risk factor will be reduced dramatically.

229 — Accelerated Aluminum Scandium Dispersoid Kinetics for Wire Arc Additive Manufacturing

Our sponsor, Relativity Space, is wire arc additive manufacturing rockets using an Al-Mg-Sc alloy. After printing, the rocket is then artificially aged in a furnace (a big one), which is costly and time insensitive, to ensure the alloy meets specifications. The aim of this project is to develop a modified 5xxx aluminum series alloy modified by additions of Si, Sc, Zr, Er, and Yb alloy with enhanced kinetics upon solidification. A series of wedge molds were cast to vary the cooling rate and assess the effect cooling rate had on the hardness and conductivity of the alloy. Isochronal and isothermal heat treatments were conducted to understand the peak aging temperature and which alloy possessed the best precipitation kinetics, respectively.

230 — Electric Tongue Jack Redesign

The sponsor of this project, Stromberg Carlson, makes RV products and is famous for an electric trailer tongue jack. The purpose of this design project is to redesign their electric tongue jack to incorporate features that make the product more competitive with other market offerings. Features like auto-leveling and hitch height memory add convenience for the customer. Bluetooth connectivity will be added to allow the customer to access these features from a smartphone as opposed to using the buttons on the jack. The technology used will be scalable to more products, such as corner leveling systems. The biggest constraint in this project is cost. In order to stay competitive, the cost of these upgrades will need to stay below $15.

231 — Effect of Mn Content Variation on Al Welding Wire Processing and Mechanical Properties

The project seeks to better understand the trade-off between wire drawability and weld strength. Currently there is only data on 0.2 and 0.6 weight percent Mn contents, from alloys 5356 and 5556, respectively. In this project, additional alloys will be cast, extruded, and drawn to assess wire and weld microstructure as well as drawability and as-welded mechanical properties.

The Air Force Research Laboratory has tasked MTU with creating an automated insertion suite to deploy situational awareness sensors for use by Special Operations Forces (SOF). This project will focus on design, prototype, and demonstration of a device or system that will provide robotic emplacement of unattended sensors in denied areas, indoors or outdoors, and in land, water, or aboveground scenarios.

233 — Forklift Auto Level

The goal of this project is to create a system to auto-level the forks on a telehandler. The current system uses hydraulics that are dependent on each other to auto-level the forks. This causes lag when the forks are first re-leveled and could be dangerous. Our system looks to use sensors to eliminate the need for dependent cylinders and to stop the lag.

234 — Development of a Beta Brass Alloy for Co-Extrusion

Due to the COVID-19 outbreak, the use of copper for highly trafficked touch surfaces throughout communities is of interest due to the element’s natural antimicrobial properties. However, because of copper’s relatively high density and cost, alternatives to the pure material must first be established and considered. One manufacturing process in particular that will decrease both the cost and density of the finalized alloy is coextrusion, where a copper-rich alloy acts as cladding to a lower-density core material such as aluminum. This study alloyed selected elements from the aforementioned groups with brass and generated a design of experiments to be used to predict the most optimal cladding composition for coextrusion that maintains antimicrobial efficacy.

235 — Proportional Integral Derivative (PID) Control Curriculum for EET

Our team was charged with developing a course curriculum using proportional–integral–derivative (PID) control for future electrical engineering technology (EET) students at Michigan Tech. Our goal is to provide students with learning opportunities that can enrich the curriculum with the control techniques used in industry.

236 — EPS Ball Nut Degrees of Freedom Optimization

Our team is working with Nexteer Automotive to improve the design of a rack-assisted electric power steering system by creating a virtual prototype in Altair MotionView, with a focus on redirecting the load path of belt tension acting on a pulley-driven ball nut and utilizing elastomers to reduce noise, vibration, and harshness (NVH) while negating the effects of misalignment between the ball nut and ball screw.

237 — WAAM Die Components

This project is the exploration of the technology and methods of using robotic wire arc additive manufacturing (WAAM) for the production of die components. The sponsor is one of the nation’s largest high-pressure die casting houses, and has routinely high tooling production costs to support. WAAM can be used to add extended features to plate products to significantly reduce the time and cost associated with removing excess material, and provides more flexibility and turnaround than casting. The focus is in lower-cost basic steels and existing MIG welding technology.

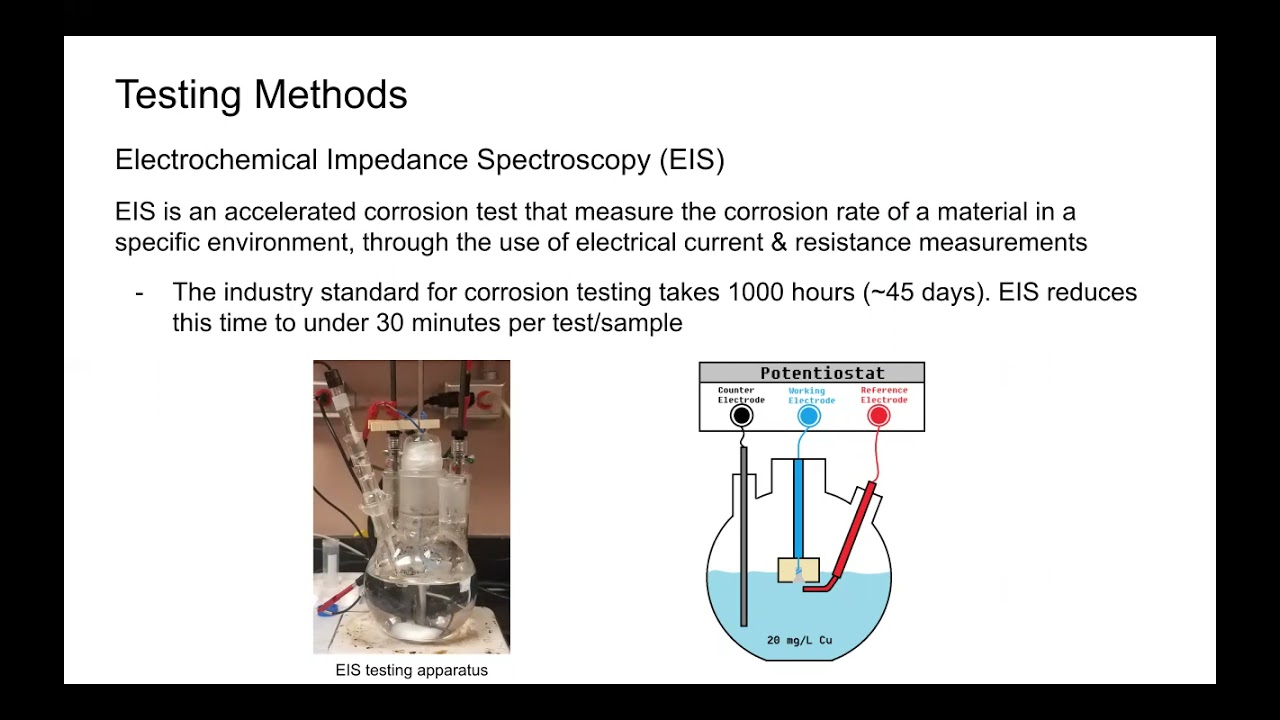

238 — Decreasing Coating System Cost to Performance Index in Steel Fasteners for Pressure Treated Lumber

Corrosion resistance of coated steel fasteners has been an issue since 2003, when the treated lumber industry switched to a micronized copper-based treatment. The micronized copper treatments created a greater galvanic potential in the wood, which causes accelerated corrosion of fasteners. Currently, approved fastener coatings for micronized copper have a high cost-to-performance index, leading to an expensive product. This project seeks to explore other coating systems that decrease cost while increasing corrosion resistance, as well as use electrochemical impedance spectroscopy (EIS) to accelerate the coating system testing and selection process.

239 — SICK LiDAR Bat Detection Device

Our team is designing a custom engine flow bench that is tuned to the needs of the sponsor. Our flow bench will include sensors to accurately measure atmospheric conditions as well as pressure drop at the test piece and flow data. Our flow bench will also be capable of running in two separate configurations—it must be able to reach the target flow rate during both push and pull.

240 — Advanced PPE Filtration System

We were tasked to design an N95-rated filtration system to be used with Stryker’s existing Flyte helmet and hood in order to protect surgeons against COVID-19 and other airborne viruses.

The teams designed and prototyped a filtration pack to be worn around the user’s waist. Filtered air is routed from the pack through tubing leading to the back of the helmet, where air is directed through the hood to the user.